Storage Tanks and Systems

Tanks and Storage Systems: Innovations & Sustainability

Tanks and Storage Systems: Shaping the Future with Innovation and Sustainability

The Backbone of Industry

What are Tanks and Storage Systems?

Containers designed to hold liquids, gases, or bulk solids for various purposes.

Range from small, localized units to massive industrial complexes.

Why are they Important?

Crucial for Supply Chains: Enable continuous production and distribution across industries (oil & gas, chemicals, food & beverage, water, pharmaceuticals, agriculture).

Safety & Security: Provide controlled environments for hazardous and non-hazardous materials.

Economic Stability: Facilitate inventory management, price stabilization, and emergency reserves.

Energy Transition: Essential for storing new energy carriers like hydrogen and for thermal energy storage.

Types of Tanks & Storage Systems

Storage systems are broadly categorized based on their contents, operating conditions, and location:

By Material Stored:

Liquids: Petroleum products, chemicals, water, food-grade liquids (e.g., milk, juices).

Gases: Liquefied Natural Gas (LNG), Liquid Petroleum Gas (LPG), industrial gases (e.g., oxygen, nitrogen).

Bulk Solids: Grains, powders, aggregates, minerals.

By Operating Conditions:

Atmospheric Tanks: Operate at or near atmospheric pressure (e.g., water tanks, some chemical tanks).

Pressure Vessels: Designed to hold contents at high pressure (e.g., LPG tanks, compressed gas cylinders).

Cryogenic Tanks: Insulated tanks for very low-temperature storage of liquefied gases (e.g., LNG, liquid oxygen).

By Location:

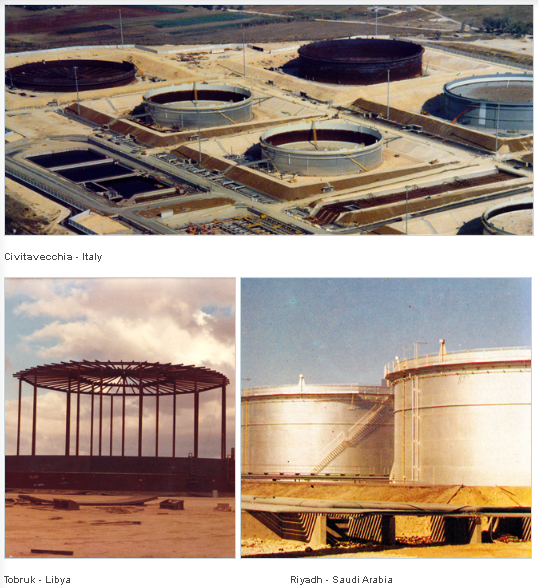

Aboveground Storage Tanks (ASTs): Visible, accessible for inspection and maintenance.

Underground Storage Tanks (USTs): Buried, conserve space, often used for fuels.

Examples of Specialized Systems:

Silos (for grains, cement)

Spherical tanks (for high-pressure gases)

Floating roof tanks (for volatile liquids to minimize evaporation)

Key Considerations in Design & Operation

Effective tank and storage system management involves multiple critical factors:

Materials of Construction:

Carbon Steel: Common, cost-effective, but prone to corrosion.

Stainless Steel: Excellent corrosion resistance, hygienic (food/pharma).

Fiber-Reinforced Polymers (FRP): Lightweight, corrosion-resistant, flexible designs.

High-Density Polyethylene (HDPE): Durable, chemical-resistant, often for water or less aggressive chemicals.

Concrete: Used for large-scale water storage, often with advanced linings.

Safety:

Leak detection and prevention.

Fire suppression systems.

Overfill protection.

Venting systems for pressure relief.

Material compatibility.

Capacity & Scalability:

Matching storage volume to operational needs.

Modular designs for easy expansion or reduction.

Regulatory Compliance:

Adherence to local, national, and international standards (e.g., API 650/653 for tanks, environmental regulations).

Regular inspections and certifications.

Latest Innovations - Driving Efficiency and Safety

The storage industry is undergoing a significant transformation driven by technology:

1. Smart Monitoring & IoT Integration:

Real-time Data: Sensors track fluid levels, temperature, pressure, structural health, and potential leaks 24/7.

Remote Management: Data transmitted wirelessly to central dashboards accessible via web or mobile apps.

Benefits: Prevents unexpected shortages, detects leaks early, optimizes usage and maintenance schedules.

2. AI & Predictive Analytics:

Predictive Maintenance: AI analyzes historical data to forecast maintenance needs (e.g., corrosion risks, equipment wear and tear) before failures occur.

Operational Optimization: Optimizes fill cycles to reduce energy waste, predicts demand, and streamlines logistics.

Automated Alerts: Instant notifications for anomalies, overfills, or contamination risks.

3. Advanced Materials & Coatings:

Corrosion-Resistant Materials: Increased use of stainless steel, HDPE, and FRP for enhanced durability and reduced maintenance.

Smart Coatings & Linings: Self-healing coatings, anti-corrosion barriers, and chemical-resistant linings extend tank lifespan and improve safety.

Modular Designs: Prefabricated components allow for faster, more economical assembly and easy scalability.

4. Automation & Robotics:

Automated Safety Systems: Self-sealing valves triggered by pressure changes, leak-detection membranes with instant shutdown protocols.

Robotic Inspection & Cleaning: Drones and robotic mechanisms for internal tank inspections and cleaning, reducing human entry into hazardous environments and minimizing downtime.

5. Energy Storage Solutions:

Thermal Energy Storage: Tanks designed to store heat or cold for later use, improving energy efficiency in industrial processes.

Hydrogen Storage: Development of specialized tanks for green hydrogen, crucial for the future energy landscape (e.g., high-pressure composite tanks, liquid hydrogen tanks).

Sustainability in Tanks & Storage - A Core Principle Sustainability is no longer an option but a necessity, integrated across the lifecycle of storage systems:

1. Energy Efficiency:

Advanced Insulation: Improved insulation materials and techniques (e.g., vacuum-jacketed, advanced foams) to minimize temperature fluctuations and reduce heating/cooling energy demands.

Energy-Efficient Pumps & Systems: Use of variable speed drives and optimized pump designs to reduce power consumption.

Heat Recovery: Systems to capture and reuse waste heat from processes.

2. Emissions Reduction:

VOC (Volatile Organic Compound) Control: Advanced venting and vapor recovery systems to capture harmful emissions from stored liquids.

Leak Detection & Repair (LDAR): Enhanced monitoring systems to quickly identify and repair leaks, minimizing fugitive emissions.

Carbon Capture Integration: Designing storage facilities to integrate with carbon capture technologies for industrial emissions.

3. Resource Efficiency & Circular Economy:

Sustainable Materials: Preference for materials with lower carbon footprints, made from recycled content, or that are easily recyclable at end-of-life (e.g., stainless steel, certain plastics).

Water Conservation: Rainwater harvesting and wastewater treatment systems for operational use within facilities.

Design for Longevity & Recyclability: Products designed for extended usability and easy dismantling/recycling.

Repurposing: Exploring ways to repurpose older tanks for alternative uses.

4. Renewable Energy Integration:

Solar & Wind Power: Using on-site renewable energy sources to power auxiliary systems (e.g., pumps, monitoring equipment, lighting), reducing reliance on grid electricity.

5. Green Hydrogen Infrastructure:

Developing robust and safe storage solutions for green hydrogen, produced from renewable energy, Slideto support the transition to a hydrogen economy.

7: Challenges & Future Outlook

While progress is rapid, challenges remain:

Challenges:

Cost of Adoption: Initial investment for advanced technologies and sustainable materials can be high.

Regulatory Landscape: Evolving environmental regulations require continuous adaptation.

Integration Complexity: Seamlessly integrating new technologies with existing infrastructure.

Public Perception: Addressing concerns related to safety and environmental impact, especially for hazardous materials.

Future Outlook:

Increased Automation & AI: More autonomous operations, self-diagnosing systems.

Advanced Composites: Lighter, stronger, and more versatile materials for diverse applications.

Decentralized Storage: Growth of smaller, modular storage solutions closer to demand centers.

Focus on Energy Transition: Continued innovation in storing renewable energy, hydrogen, and carbon.

Enhanced Cybersecurity: Protecting smart storage systems from cyber threats.

Digital Twins: Creation of virtual replicas of physical tanks for real-time monitoring, simulation, and predictive analysis.

Conclusion - A Sustainable and Smart Future

Tanks and storage systems are fundamental to modern industry and society. Latest innovations in IoT, AI, and materials are making these systems safer, more efficient, and more reliable. Sustainability is a driving force, leading to reduced environmental impact through energy efficiency, emissions control, and circular economy principles. The future promises even smarter, more integrated, and environmentally responsible storage solutions, essential for global energy security and industrial resilience.