OUR PROJECTS

Plastic Waste Management Plant

Turning Plastic Waste into an Energy Source

Executive Summary

It is everyone's dream now, and we are able to make it come true.

Melete's goal is to assess the economic feasibility of developing a large plant for recycling plastic and other waste materials using a new technology.

We are able to apply this technology.

Before the war in Ukraine, waste was in the hands of a few, the waste lobby.

One country has already planned to build the first large plant: Slovakia.

The concept

Waste has been produced since the beginning of humanity. While in previous centuries, due to the prevalence of organic waste, this was not a problem, the situation changed at the latest with the industrial revolution. Initially, the procedure was the same as described above and the waste was simply disposed of where it was no longer visible, and could then be forgotten. The long-term consequences of this practice had not yet been considered. Until the 1950s, landfills in Italy and Germany were also illegal dumps or, at best, holes dug into the ground.

Most of these were private landfills, operated in an uncontrolled manner and without much expertise. Since the end of the 1950s, landfills in Italy, Germany and in all countries have at least been sealed against groundwater and, later, also against rainwater. However, in 1971, a uniform legal basis for waste disposal was created with the Waste Disposal Act.

The Project

The waste problem threatens to grow out of all proportion.

In the 1970s, landfills were considered to be huge processing plants for organic waste. Due to the growing volume and the long reaction times until the organic processes decay, alternatives to traditional and primitive landfills have been sought since the 1980s. In the meantime, landfills have continued to grow uncontrolled. Especially industrialized countries are producing ever greater quantities of waste. In Germany alone, the percentage of waste days increased by 38 percent from 1976 to 1996. In total, the volume of waste from the environment increased from 31 tonnes to 42.7 tonnes per capita during this period. Other industrialized countries can boast of a similar development. If other countries like China had consumed similar quantities of substances since the beginning of industrialization, we would already have an irreversible waste problem.

And now the war in Ukraine has come, which has caused all previous energy prices to skyrocket for everyone.

It is true that the shift from heavy industry to e-commerce is again saving resources. However, this is offset by global economic growth and consumer enjoyment of an energy- and material-intensive lifestyle. This is particularly evident in the growing incidence of plastic waste. According to the Association of Plastics Manufacturers (Plastics Europe Deutschland e.V.).

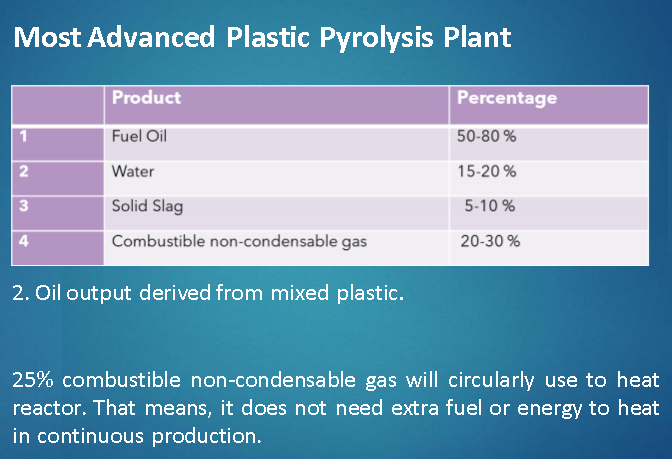

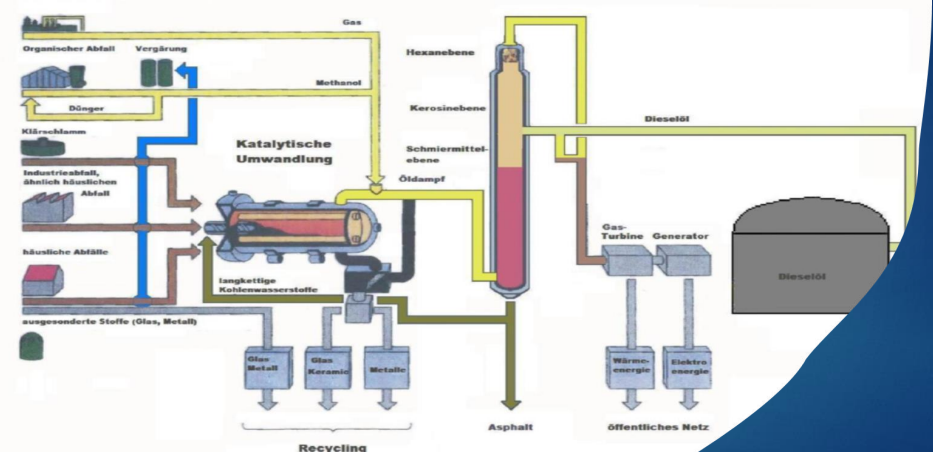

The project involves the recycling of petroleum-based waste. Other materials such as textiles, wood and even household waste can also be reused with our system.

- The first, but not the most important, product of this conversion is crude oil, which must be processed for further use in the refinery.

- The second is gas.

- The third emerging element is electricity. This can be fed into the grid. A small part is used by the system itself or we produce hydrogen!

Technology and competitive advantage

The following is a detailed description of the technology and the associated systems. At this point, it is only mentioned that in this process, long hydrocarbon chains are shortened by heat treatment to those of diesel or heating oil. This is therefore an isolated case: on the one hand, the operators of such plants earn money by accepting the waste, in order to then use this legal form. On the other hand, after recycling, by selling the heating oil or diesel.

Anyone who has doubts about the appropriateness of laboratory tests as a basis can rest assured: the procedure is not new. It was already developed and tested in the 1970s by BASF and Aral.

Proof of its functionality had already been provided at that time. However, since such plants were not profitable due to the falling oil price and no one could predict how much the price of diesel would rise, the project was discontinued and shelved.

With diesel prices now above 1.80 euros, however, the situation has changed dramatically and the technology is more volatile than ever.

Of course, the technology is no longer the same as it was in the 1970s, but it has been continuously optimized and made more efficient over the past ten years, so that today we can speak of a true technology of the future. The catalytic process used now has an efficiency of up to 95%.

Thanks to the corresponding patents, the technology is also largely protected, so that its successful commercial exploitation no longer poses any obstacles.

Benefits for the country

- Dwindling oil reserves and rising oil prices:

Diesel fuel and diesel fuel are the backbone of industrial society. With rising oil prices, investing in this technology is becoming more profitable, as demand is constantly growing.

- Unsolved global and national waste disposal:

The growing number of landfills and the limited exploitation possibilities require a solution. Therefore, plastic waste is exported to China at high costs and the utilization rate is currently only 58%. China has now banned the import of plastic waste.

- Above-average high yield:

A decentralized recycling plant offers waste disposal companies an above-average high yield. This technology is far superior to alternative disposal solutions such as waste incineration.

• Safe sales market:

Again, no special explanations are needed: everyone knows what diesel is used for.

• Obvious risk, even for non-experts:

For many companies, an outside observer cannot easily assess whether the proposed business idea works and the risks associated with it.

• Here the risk is clear:

Either there is no more waste, or diesel is no longer needed. Both situations are easy for non-experts to calculate.

___

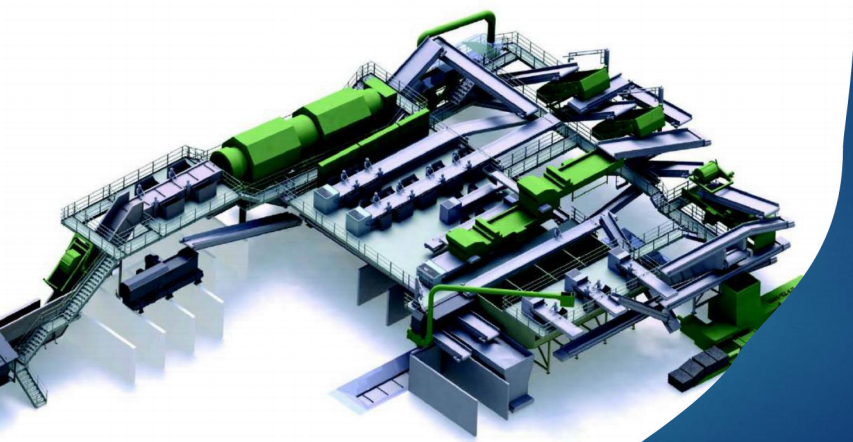

Description of our Plant

- Territorial Applicability:

- Total size of the land : 10 - 20,000 mq

- Factory: 2,500 mq

- Office building : 2,000 mq

- Outbuildings, office, workshop, canteen, sanitary facilities, etc.: 1,000 mq

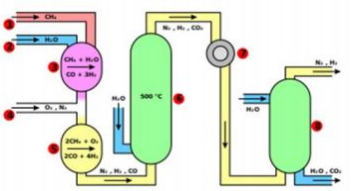

Distillation plant - steam reformer

The evacuated vapours now enter the distillation unit. During this distillation, the vapour is slowly cooled and becomes liquid again. The result is so-called crude oil, which is approximately a mixture of crude oil and does not contain impurities or sulphur. In this form, it is not intended for use in internal combustion engines. In a further processing step, the crude oil is refined. Here we only extract a diesel precursor. The result is therefore a fuel with viscous properties similar to diesel.

Not suitable for use in cars or trucks due to the high cetane content, but

optimised for use to generate electricity in corresponding generators.

Cetane content in diesel fuel according to DIN EN 586 approx. 56.

Our oil approx. 68-70.

DIOXINS and FRENONE

Dioxins are 1,000 times more toxic than arsenic. Dioxins are formed when chloride-containing plastics, such as PVC, are processed at 280-800 degrees Celsius. We simply need to convert it before 280 degrees Celsius so that dioxins cannot be produced, and then reheat it and pyrolyze it in a safe and environmentally friendly way. Now, whether it is an external rotary reactor or a single reactor, the technical problem cannot be solved. Because the temperature in a single reactor is basically uniform, that is, it should reach 400-550 degrees Celsius before pyrolysis, in other words, the reactor cannot pyrolyze without reaching this temperature. However, this is the best condition for the synthesis of dioxins in large quantities, that is, between 400 and 550 degrees Celsius.

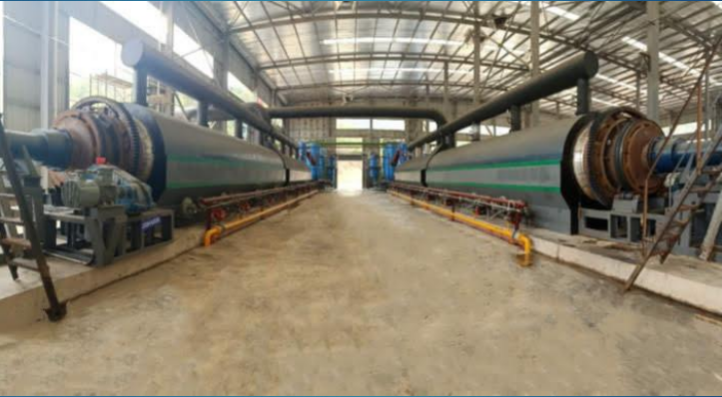

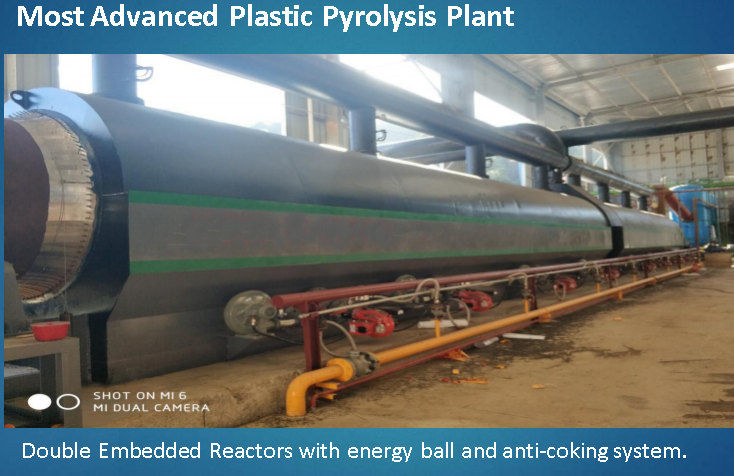

Advanced hierarchic pyrolysis technology

The company, which has developed a "modular" combination system of continuous reactors, was able to solve this important problem because each device is separate (but connected in series with each other). With reactors No. 1 and No. 2 at a temperature below 280 °C, and the addition of chloride catalyst, the generation of dioxin is completely eliminated, making the continuous pyrolysis process in reactors extremely safe and environmentally friendly.

- Our pyrolysis plant is equipped with an automatic feeding system. The material goes from underground to the feeder and from there enters the reactor, or it is possible to use a wind feeding system, both automatic. In addition, there is no dust dispersion in the workshop.

- We have energy-saving technology: the fuel is heated indirectly at the bottom of the reactor (flame facing down), with 8 burners installed evenly on the reactor, which can transfer heat energy evenly at 360 °C. In this way, it saves a lot of energy and protects the reactor, extending its life. - Currently, the main problem for continuous production of rotary reactors is the continuous formation of thickening coke when the feed materials are subjected to high temperatures in the reactor, which not only prevents the reaction from proceeding, but also quickly damages the equipment. We have the "Energy Ball" technology that can continuously remove the coke from the reactor to ensure feeding and pyrolysis, greatly extending the life of the equipment and increasing production efficiency.

- During the heating process, the reactor automatically and slowly rotates regularly for 3 minutes per cycle, and the material is completely pyrolyzed from one end to the other.

- The syngas generated by the system is used to support continuous heating. The fully continuous system does not require additional fuel once it is started. Since the syngas is far enough away for heating, this saves a lot of fuel costs.

- Thanks to our special soft sealing technology, the entire pyrolysis system is completely airtight and leak-free. Therefore, no harmful gases or bad smells escape from the system. The system is equipped with an automatic depressurization valve, so the pressure inside the reactor will never be dangerous.

- We use water tanks only for cooling (not N₂). Water is used circularly from equipment to tank, which saves a lot of daily costs.

- Multi-grade discharge system with water pumping ensures low temperatures during discharge.

- Once started, it can run continuously for 8000 hours. However, we recommend stopping it every 2-3 months for periodic checks or maintenance. Unlike batch plants, which need to heat and cool the reactor every day, the plant is prone to failures due to heating and cooling and is also very dangerous, with explosions occurring every year. Therefore, continuous plants are safe and have a much longer lifespan than batch plants.

- All our systems have obtained ISO, SGS and CE certifications.

- Advanced sulfur removal technology. In the tire reaction, by adding new sulfur fixative to the reactor, the sulfide of the feed material solidifies by complexation, and the gasified sulfide is absorbed, thus preventing the emission of sulfide into the final oil and air.

- Advanced electronic device control technology. To ensure precise and smooth production operation, the key components of the device are equipped with digital instruments that centrally manage all data, thus greatly improving the controllability of operation and timely troubleshooting.

Environmental protection and safety

1) No dust. The main pyrolysis system operates under normal pressure. This means safe operation in a fully enclosed equipment.

2) Non-condensed gas.

3) The recycled non-condensed gas can be directly transferred to the heating system to support continuous production. If there is a problem in the system, the heater can be turned off and the heat source can be cut off immediately to ensure the safety of the system.

4) A double safety device and an alarm device are installed on each key component.

Plant description and construction costs

Our system can process up to 300,000 tons of plastic waste per year.

To limit the investment until the first start-up, our system is divided into modules. Each module has a processing capacity of 60,000 tons per year.

The cost per module is 60,000,000 euros (sixty million euros), including the land (plant).

First phase: Costs include:

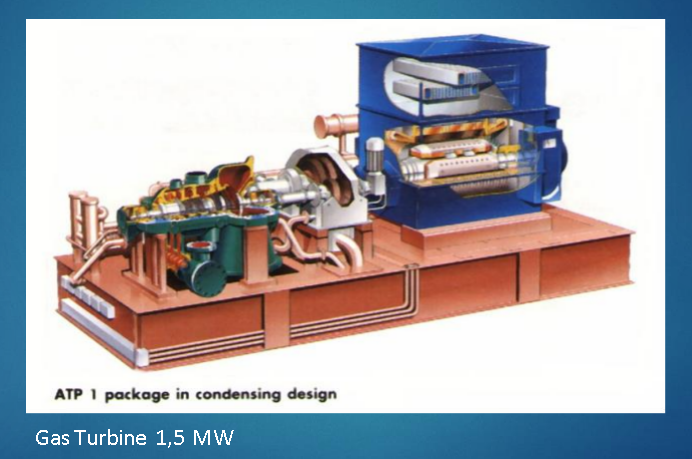

Purchase of land, design, architectural and construction design, workshop 65x45 m and 9 m high, office building, 4 complete production lines, including condensation system, pump station ventilation system, control and monitoring system, 3 shredders, 6 oil storage tanks of 40,000 liters, including safety tank in accordance with the law, toilets, waiting rooms, first aid station, 2 complete turbine generator sets from NOK with a capacity of 1.5 MW, complete truck filling station, 2 forklifts, 2 trolleys, complete workshop for repairs and maintenance of mechanical components and heavy metals, 2 drawer unloaders for delivery and cleaning equipment.

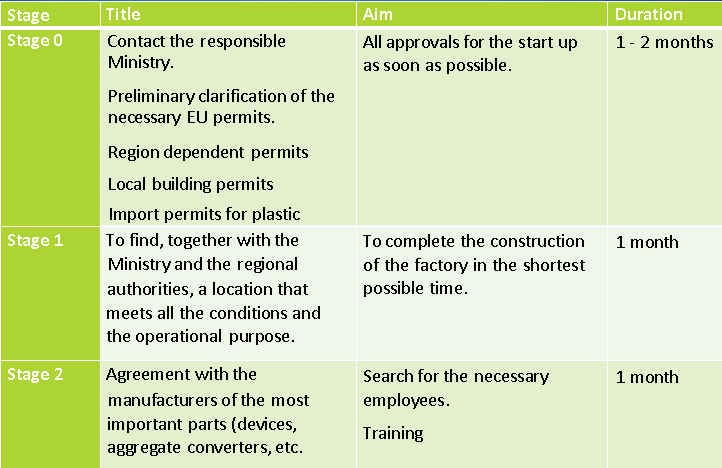

Advance Strategy